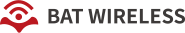

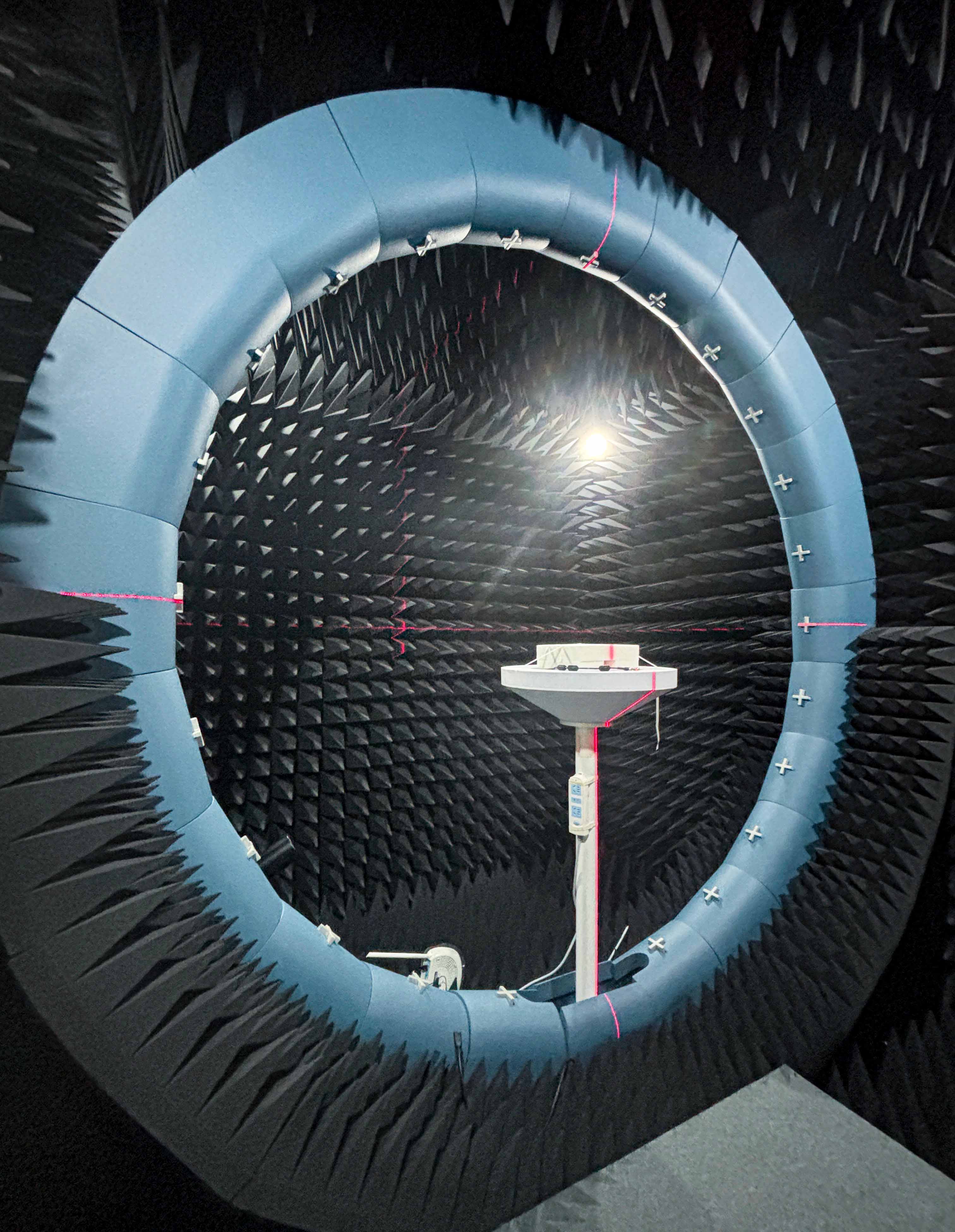

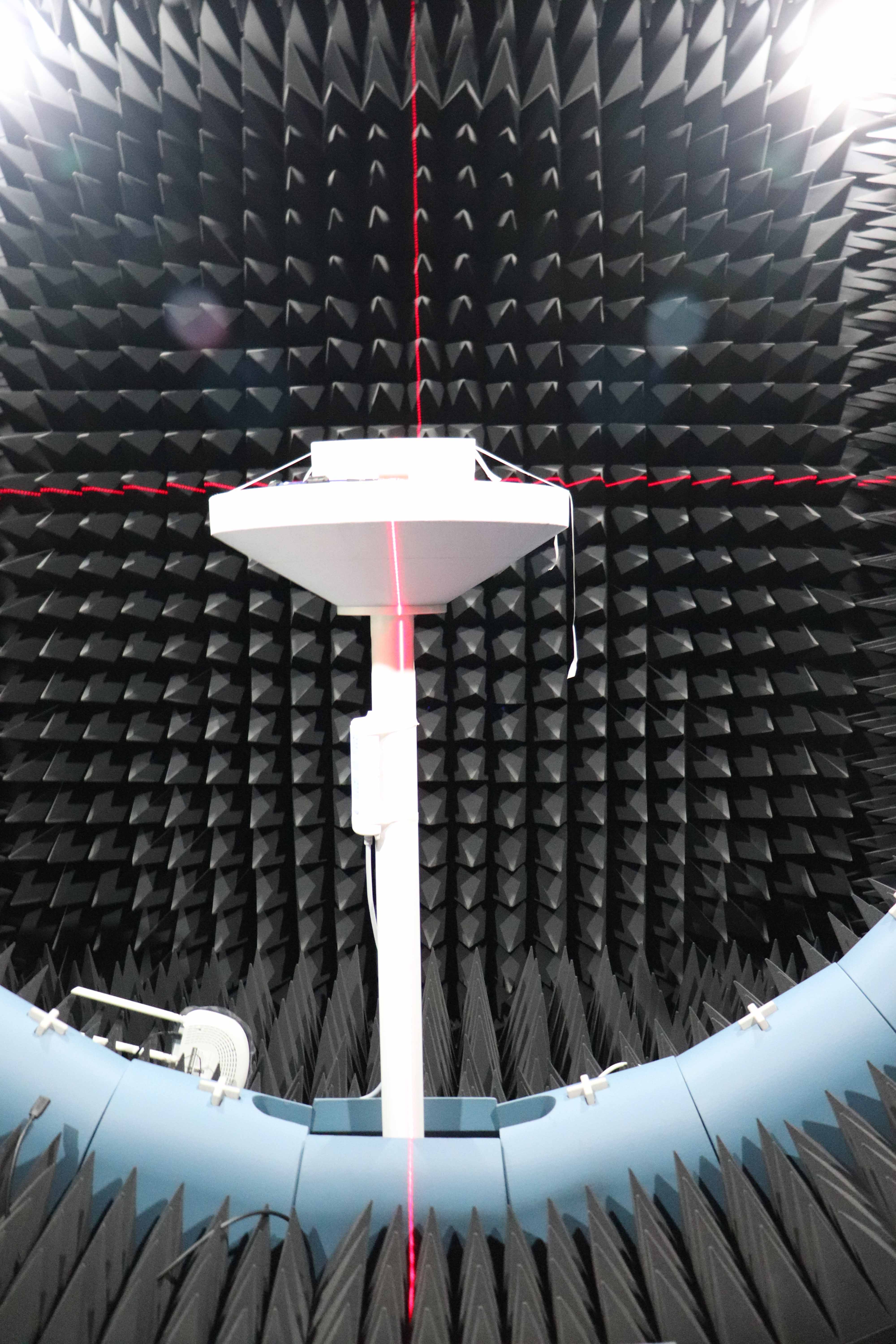

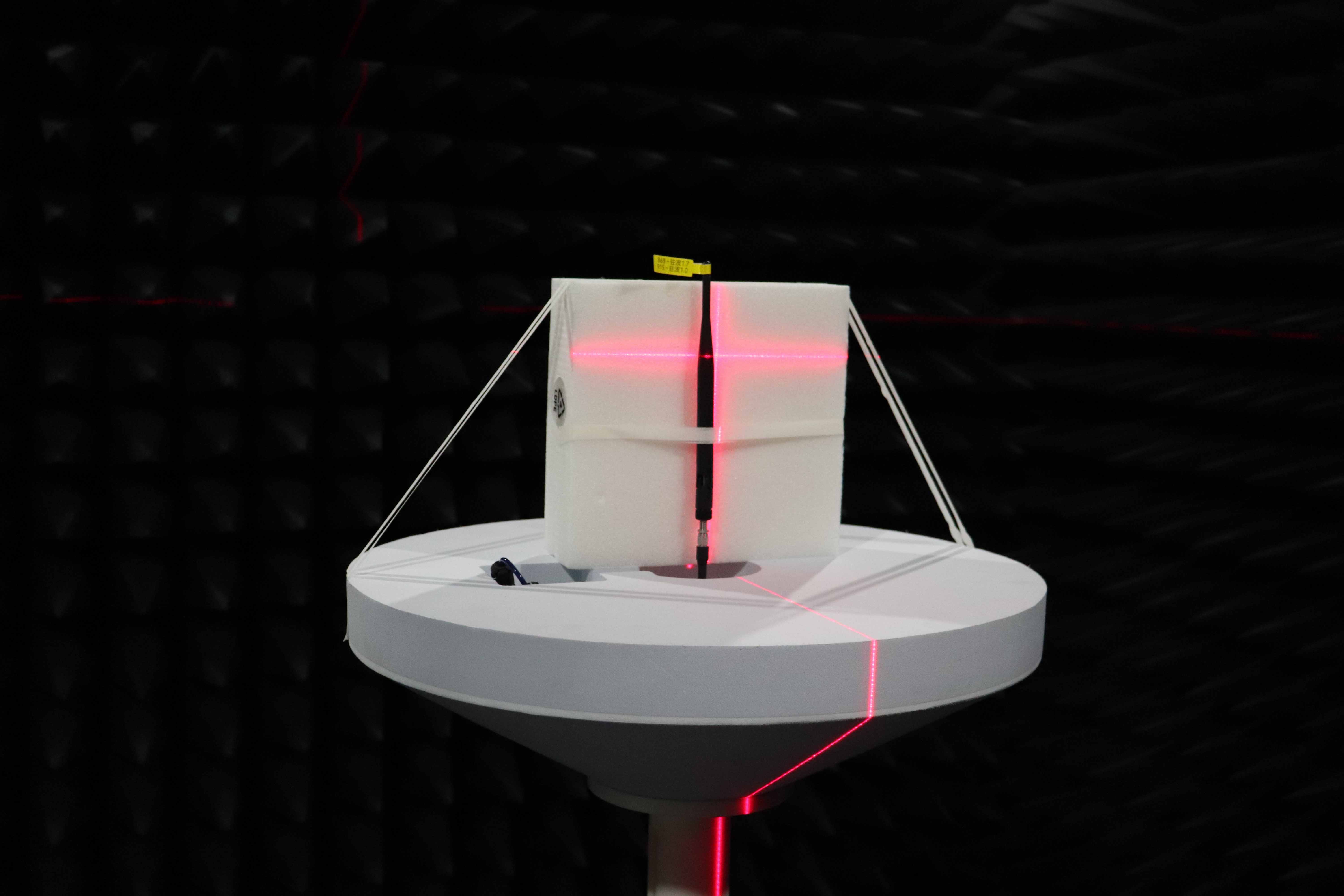

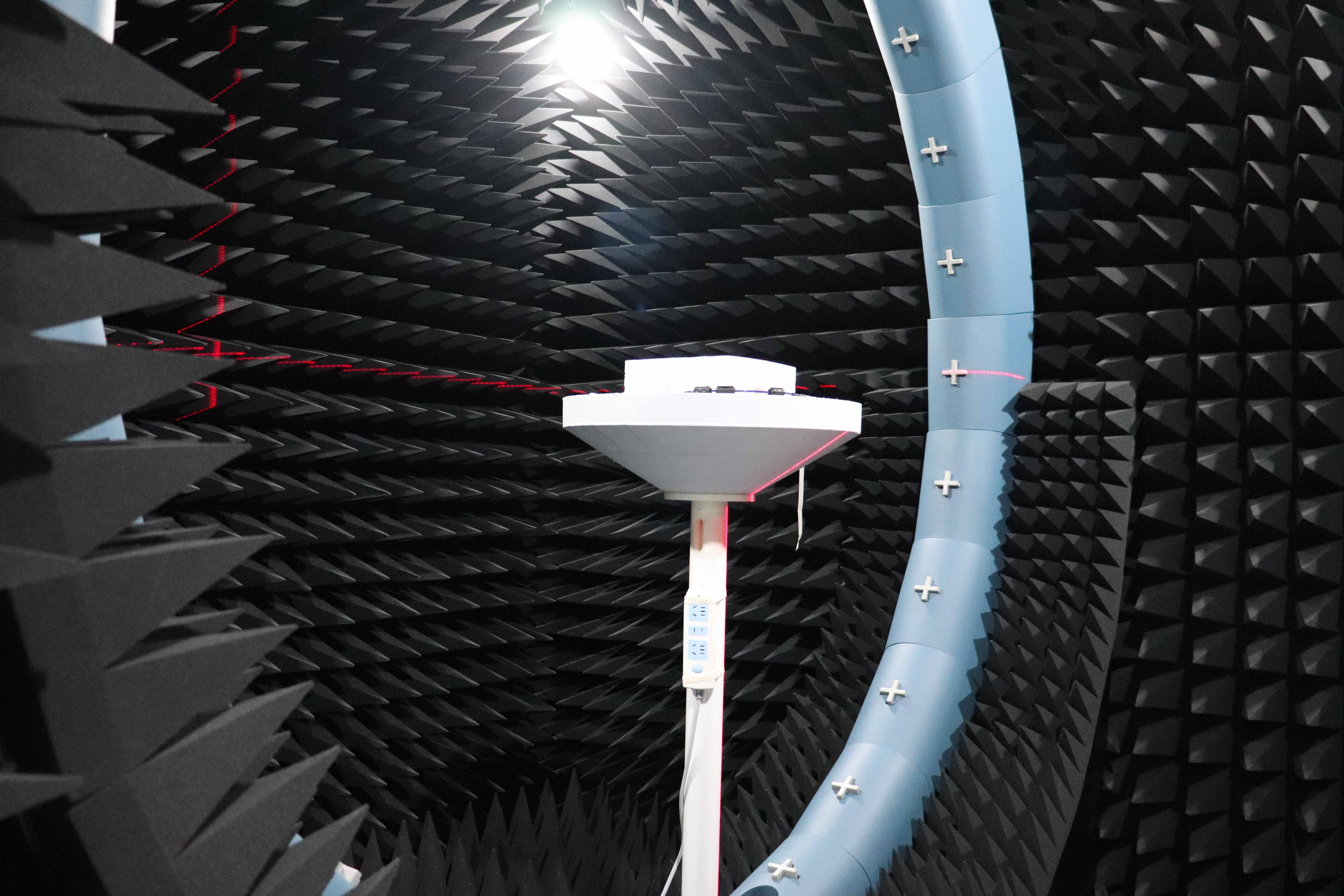

Anechoic chamber testing validates antenna radiation performance and compliance through standardized procedures and precision instruments, offering critical data for product optimization and certification.

Client Provides:

- IoT devices, 5G base stations, radar systems, medical equipment

- Single/multi-band (e.g., 2.4+5 GHz or 28 GHz mmWave)

- 3 dBi (omni) to 20 dBi (directional)

- Linear (V/H) or circular polarization (RHCP/LHCP)

- Max dimensions (e.g., 15×15×5 mm)

Our Prepares:

- Calibrates test equipment (VNA, signal generator, reference antennas)

- Validates chamber performance (background noise ≤-50 dBm, reflectivity ≤-40 dB).

Deliverable: Test Plan Document.

Test Item

Method/Equipment

Key Metrics

S-Parameters

Vector Network Analyzer (Keysight PNA)

S11 (Return Loss), S21 (Isolation)

Impedance Matching

Smith Chart Analysis + TDR

VSWR ≤2.0

Frequency Coverage

Frequency Sweep (0.1 GHz steps)

-10 dB Bandwidth Coverage

Test Item

Method/Equipment

Key Metrics

Radiation Pattern

Turntable + Standard Gain Horn (ETS-Lindgren)

H/V-Plane Patterns, 3 dB Beamwidth

Gain Measurement

Substitution Method

Peak/Average Gain (dBi)

Efficiency Test

Wheeler Cap/Radiation Integration

Total Efficiency ≥50%

Cross-Polarization

Orthogonal Polarization Switching

≥15 dB (Circular Polarization)

Side-Lobe Suppression

High-Resolution Angular Scan (1° step)

Side-Lobe Level ≤-10 dB

- Thermal Cycling: Pattern stability at -40°C to 85°C.

- Vibration Test: Post-random vibration (10–2000 Hz) validation.

- Salt Spray Test: 48-hour exposure for corrosion resistance.

- Pattern Optimization: 3D interpolation using MATLAB/Python.

- Efficiency Calibration: Loss compensation via integrating sphere data.

- Compliance Check: FCC Part 15/ETSI EN 300 328 standard alignment.

- Test setup (equipment list, chamber specs).

- Raw data plots (S-parameters, polar radiation patterns).

- Pass/Fail summary with improvement recommendations (e.g., bandwidth optimization).

- Formats: PDF + stamped hard copy.

- Free Retest: 1 free retest for failed items (within 30 days).

- Expedited Service: 24-hour turnaround (+30% fee).

- Pre-compliance reports (FCC/CE).

- Design modification support for certification.