Prototyping Process

This standardized process ensures efficient concept-to-product transition through a simulation-driven design, rapid iteration, and reliable mass production framework.

Stage 1:

Requirement Finalization & Design

1.1 Requirement Analysis Meeting

- IoT devices, 5G base stations, radar systems, medical equipment

- Single/multi-band (e.g., 2.4+5 GHz or 28 GHz mmWave)

- 3 dBi (omni) to 20 dBi (directional)

- Linear (V/H) or circular polarization (RHCP/LHCP)

- Max dimensions (e.g., 15×15×5 mm)

1.2 Simulation & Design

Tools: HFSS/CST/ADS for electromagnetic simulation

Design Steps:

- Initial structure design: Patch/IFA/slot antenna selection

- Parameter tuning: Feedline width, ground plane slots, parasitic elements

- Simulation validation: S11 curve (<-10 dB bandwidth),radiation efficiency (>60%), 3D radiation pattern

2.1 Material & Process Confirmation

Material Type / Applications

- FR4 / Low-cost, low-frequency (<3 GHz)

- Rogers 4350B / High-frequency/mmWave (5G/satellite)

- Flexible substrates (PI/PET) / Wearables/curved surfaces

2.2 Prototype Fabrication

PCB Antennas:

- Fabrication: 4-layer ENIG plating, impedance control ±10%

- Assembly: 0402 components hand-soldered, X-ray inspection

Structural Antennas:

- Metallization: LDS or electroless nickel/gold plating

2.3 Initial Testing

VNA testing: Keysight PNA with probe-tip calibration

- VSWR <2.0 in target band

- Return loss S11 <-10 dB

Stage 2:

Prototyping & Initial Testing

Stage 3:

Debugging & Optimization

3.1 Impedance Matching Tuning

Tools

- Smith Chart analysis

- Copper tape modification

Procedure

- Tune series/parallel LC for 50Ω match

- Test bandwidth extension with patches

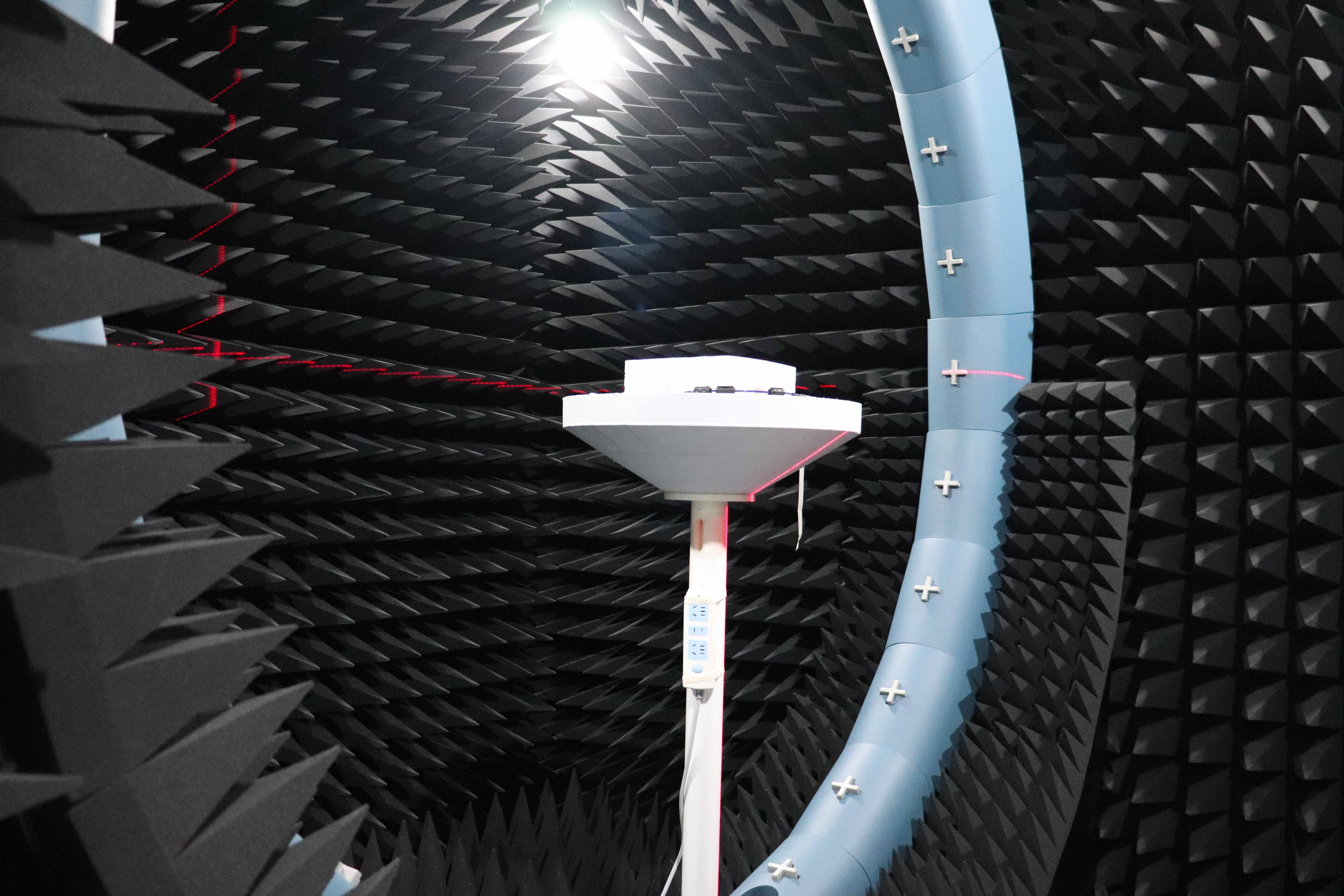

3.2 Radiation Performance Validation

- Gain measurement: Reference horn antenna comparison

- Radiation pattern: H/V-plane polar plots (3 dB beamwidth ≥120°)

- Metal housing compensation: Decoupling structures/absorbers

3.3 Issue Resolution

Common Issues

- Frequency shift

- Insufficient bandwidth

- Low efficiency

Solutions

- Tune radiator length ±0.2λ

- Add parasitic elements/stub matching

- Verify dielectric loss (low-tanδ material)

Stage 4:

Final Validation & Delivery

4.1 Reliability Testing

Test Items

- Thermal cycling

- Vibration test

- Salt spray test

Standards

- -40℃~85℃, 5 cycles

- 20G@10-2000 Hz, 3 axes ×1 hr

- 5% NaCl, 96 hrs (outdoor models)

4.2 Deliverables

- Prototypes: 3-5 functional samples (with mounts/connectors)

- Schematics/PCB Gerber files

- Antenna Test Report (anechoic chamber data) Mass Production Guidelines (pad dimensions/tolerances)

Stage 5:

Mass Production Transition (Optional)

5.1 Pilot Production

- Process validation: FAI & CPK analysis (key dimensions ≥1.33)

- Test jigs: Automated RF test fixtures (≤30 sec/unit)

5.2 Special Antenna Considerations

Antenna Type

- mmWave antennas

- Flexible antennas

Key Requirements

- Laser drilling ±0.02 mm, Ra<0.5μm

- Bend test (10k cycles, R=3 mm)